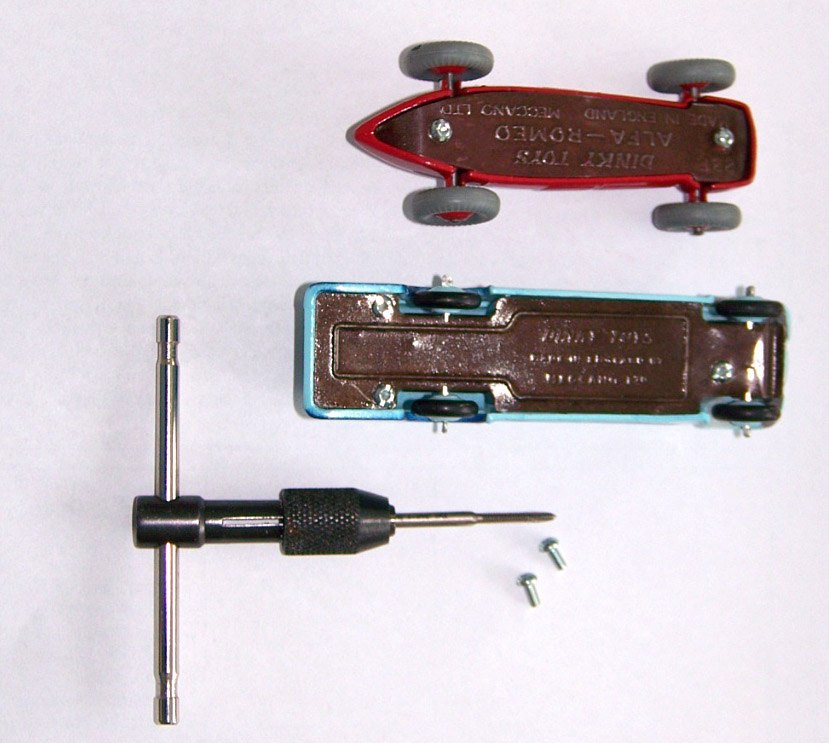

Removal of the chassis from the body is done by drilling a pilot hole into the center of the rivet followed by a larger drill to break off the head. The pilot hole has to be a certain size to accommodate the replacement rivet or screw. The rivets that are sold for this task resemble the original and for retaining the original look then go this way.

But I am not for creating something that is not easy to undo, so I go for a 4-40 thread screw. Similar sizes can be used but I find this one quite adequate. The correct drill is #43 .089 inches, you can use a 5/64 for a tighter fit. So the initial pilot hole has to be this size and drilled as far as you dare, but try not to go right through the body.

Tapping is done by using a taper to get started and then, depending on the depth of the hole, use a plug or even a bottom tap. These definitions are so that you can cut a thread nearer to the bottom of the hole. If the depth is not sufficient for the length of screw, I use 1/4 inch, then cut the screw down to the required length.

To cut the screw I use a piece of 1/8 inch flat metal with a threaded hole. Put the screw through the hole and cut off and file the end.

But I am not for creating something that is not easy to undo, so I go for a 4-40 thread screw. Similar sizes can be used but I find this one quite adequate. The correct drill is #43 .089 inches, you can use a 5/64 for a tighter fit. So the initial pilot hole has to be this size and drilled as far as you dare, but try not to go right through the body.

Tapping is done by using a taper to get started and then, depending on the depth of the hole, use a plug or even a bottom tap. These definitions are so that you can cut a thread nearer to the bottom of the hole. If the depth is not sufficient for the length of screw, I use 1/4 inch, then cut the screw down to the required length.

To cut the screw I use a piece of 1/8 inch flat metal with a threaded hole. Put the screw through the hole and cut off and file the end.

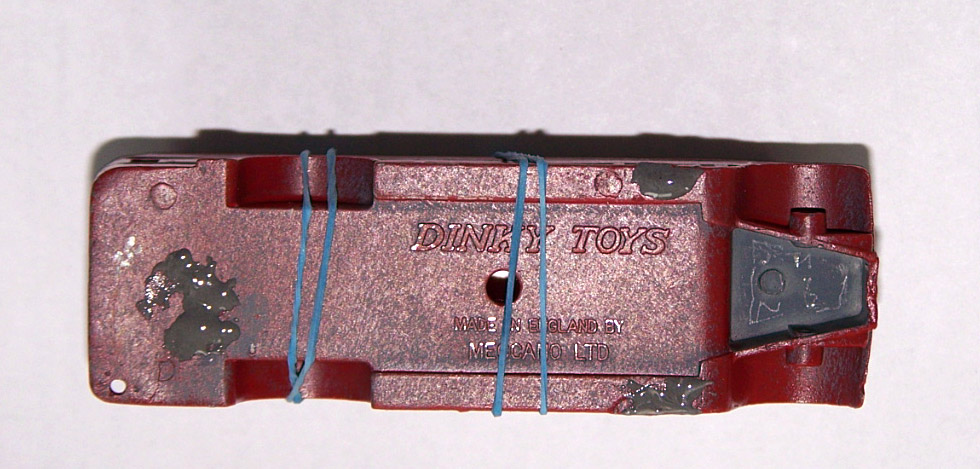

Some models do not use rivets. For instance the Double Deck Bus 290, uses tabs that are punched to hold the chassis. I have not really found a good method for this. At present I use a dab of metal based epoxy resin, which is easy to grind out should separation be necessary again.

Some models do not use rivets. For instance the Double Deck Bus 290, uses tabs that are punched to hold the chassis. I have not really found a good method for this. At present I use a dab of metal based epoxy resin, which is easy to grind out should separation be necessary again.

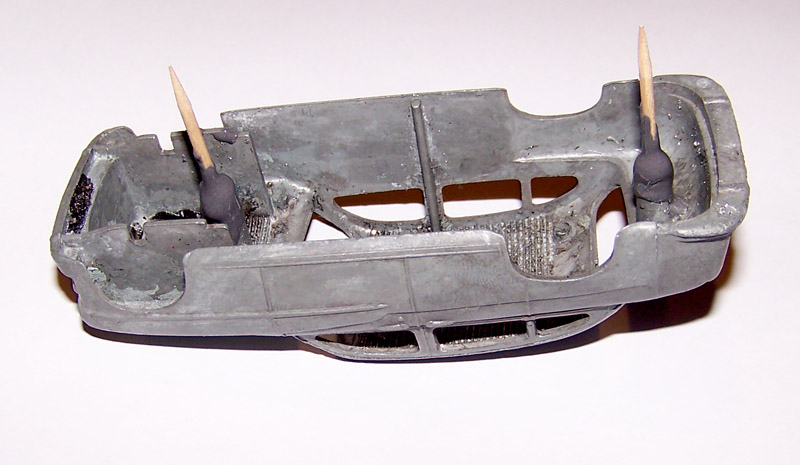

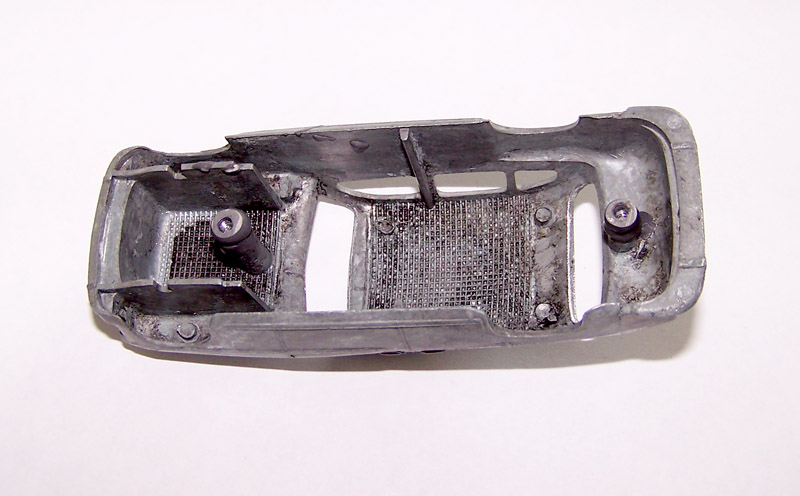

I came across a Ford Vedette that was damaged.

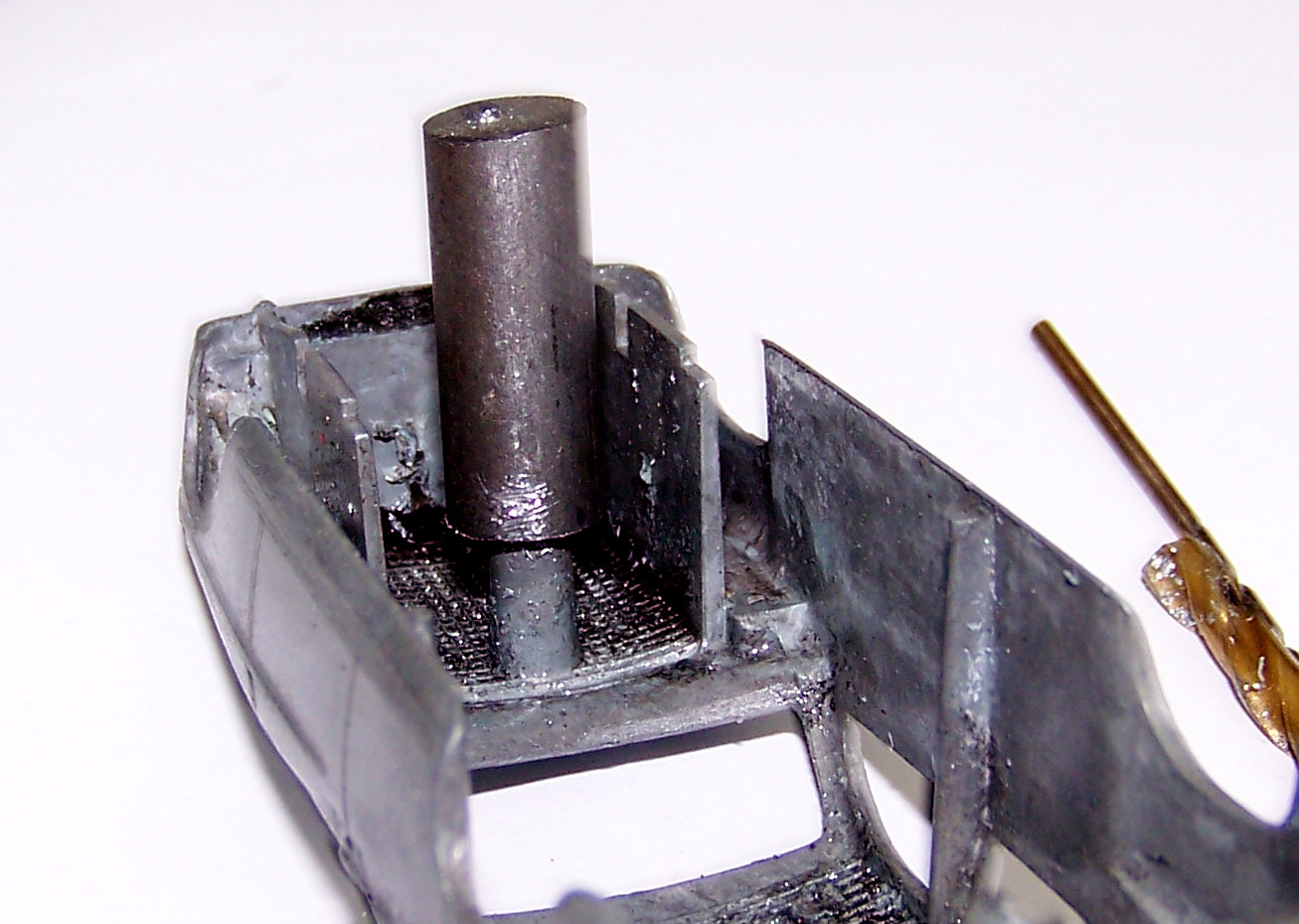

This model was already in pieces, but the pillars used to rivet the base on were in poor shape as was the chassis. The main problem was how to drill the pillars and repair them so they can be usefully used again.

I made up an alignment tool which was a piece of metal bar drilled first with a small drill to the size that you want the finished size to be for re riveting or tapping and screwing. Next the bar was drilled 1/2 way with a drill the size of the pillar.

By dropping this tool over the pillar the smaller size drill is now aligned centrally over the pillar and the pillar can be drilled.

The tops of the pillar can now be filed down to the correct length and a tooth pick inserted to maintain the hole while some metal based epoxy can be applied to reinforce the pillar. The tooth pick is easy to file flat and drill out.

I came across a Ford Vedette that was damaged.

This model was already in pieces, but the pillars used to rivet the base on were in poor shape as was the chassis. The main problem was how to drill the pillars and repair them so they can be usefully used again.

I made up an alignment tool which was a piece of metal bar drilled first with a small drill to the size that you want the finished size to be for re riveting or tapping and screwing. Next the bar was drilled 1/2 way with a drill the size of the pillar.

By dropping this tool over the pillar the smaller size drill is now aligned centrally over the pillar and the pillar can be drilled.

The tops of the pillar can now be filed down to the correct length and a tooth pick inserted to maintain the hole while some metal based epoxy can be applied to reinforce the pillar. The tooth pick is easy to file flat and drill out.